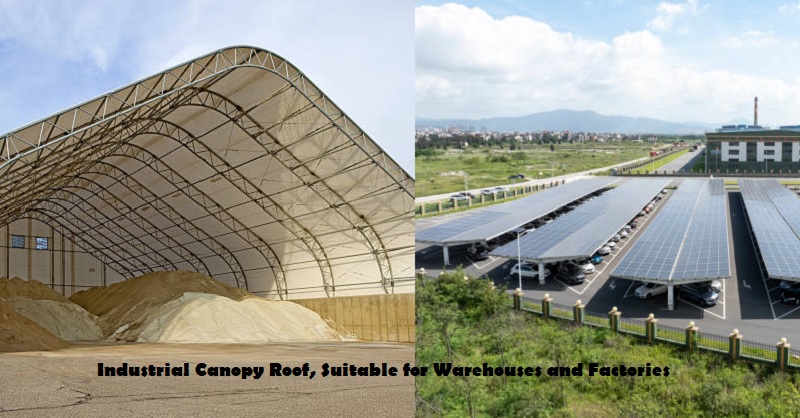

In the industrial sector, the need for efficient and durable infrastructure is crucial. One vital element supporting these operations is an industrial canopy roof. These roofs are often designed to meet the needs of various sectors, from manufacturing and logistics to warehousing and distribution centers.

Industrial Canopy Roof and Their Appeal Compared to Other Options

As previously mentioned, modern industry requires flexible, yet strong and economical building solutions. This is why canopies are often considered over other types of roofing.

One reason is their ability to withstand various weather conditions, including rain, hot sun, strong winds, and pollution. This is crucial for maintaining worker productivity and the condition of the goods stored within.

Furthermore, industrial areas often require large spaces without main support pillars, especially for activities such as loading and unloading, production, or storage. Therefore, canopies are more suitable than roof tiles.

For example, in the logistics building construction we can see on the Field and Lawn YouTube channel, the building frame uses an open canopy roof design. This allows workers to freely carry out their tasks without fear of being obstructed by objects around the building. Design and energy efficiency are also important considerations. A canopy designed with natural ventilation and lighting can reduce electricity consumption, especially for cooling and lighting.

Another equally important consideration when choosing an industrial canopy roof is ease of maintenance. Canopy materials are highly resistant to corrosion, weather, and heavy loads. This means lower maintenance costs.

Recommended Industrial Canopy Materials

To reap the benefits mentioned above, careful selection of canopy materials is crucial. This is because material selection is key to designing a canopy that meets your needs and budget. Here are some popular materials.

1. Polycarbonate

The first choice is polycarbonate, made from a special polymer. This creates a cleaner and clearer appearance. It is ideal for areas that require natural lighting. Compared to glass, polycarbonate is much lighter and easier to install. This roof is also UV-resistant and can last up to 10 years. The installation design itself tends to be gabled. Its simple shape is sloped for optimal rainwater drainage. It is suitable for warehouses or factories.

2. UPVC

UPVC, made from unplasticized polyvinyl chloride, is also suitable for Industrial canopy roof. One of its advantages is its flexibility and adaptability to various building designs. This roof is also heat-resistant, shatterproof, and even noise-absorbing.

UPVC canopy roofs are available in two types: single-layer and double-layer. Typically, the curved canopy is installed, providing a modern and aesthetically pleasing appearance. This design is often used in loading docks or logistics facilities.

3. Light Steel

Finally, there are lightweight steel canopies, known for their strength. These canopies are ideal for industrial environments that require large yet economical structures. Industrial owners typically adopt elongated designs to protect outdoor areas, such as industrial vehicle parking areas or loading and unloading areas. For optimal performance, users can add ventilation holes or skylights. This aims to increase air circulation and natural lighting, resulting in significant energy savings.

What is the Difference Between Industrial Canopy Roofs and Other Types?

Of course, the use of this type of canopy is very different from other types of canopies. Industrial canopies are intended for specific sectors, such as logistics, factories, and so on. They are also less suitable for residential use, as they have a slightly different function and appearance. The designs themselves also tend to be more rugged, depending on the material and application.

Industrial canopy roof are a significant investment in protecting assets while increasing productivity. Always remember that the right material and design must be tailored to the specific needs of each industry, such as weather conditions, operational activities, and budget. /ame